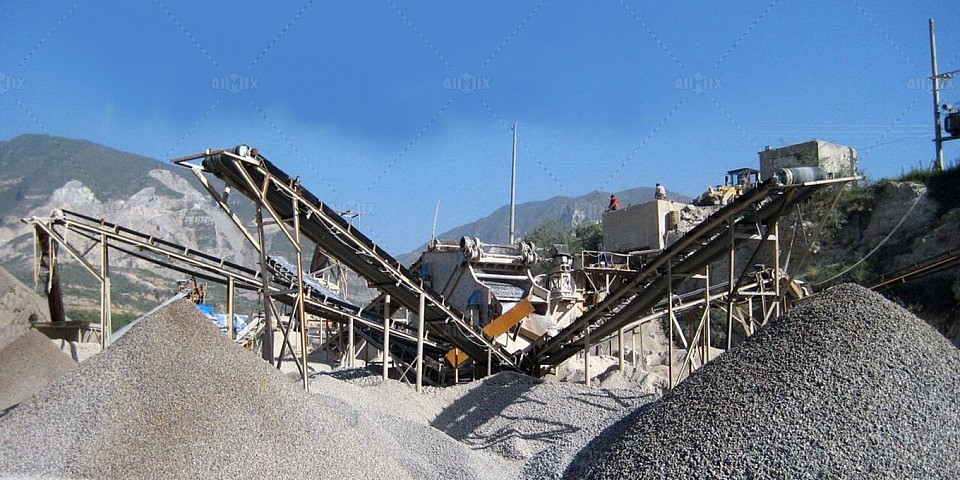

Calculating the Right Quarry Stone Crusher Size for Your Aggregate Production Goals

Determining the appropriate size of a quarry stone crusher is essential for achieving optimal aggregate production. The right quarry stone crusher machinery size can streamline operations, reduce costs, and ensure the desired output quality. This article delves into the critical factors that influence the selection of crusher size, offering insights to help you make an informed decision for your quarry operations.

Understanding Your Aggregate Production Goals

Project Scale and Output Requirements

The scale of your project and the specific output requirements play a pivotal role in determining the right crusher size. Large-scale projects necessitate robust crushers capable of handling substantial volumes of material. Conversely, smaller projects may benefit from more compact machinery. It's imperative to assess the daily and monthly production targets to ensure that the chosen crusher can meet the demand without overloading or underperforming. Consider the desired aggregate size and consistency, as these factors will influence the crusher's specifications and capabilities.

Material Characteristics and Hardness

Another crucial consideration is the nature of the material being processed. Different types of stone exhibit varying degrees of hardness and abrasiveness, which can impact crusher performance. For example, granite and basalt are significantly harder than limestone and sandstone. The crusher must be capable of efficiently processing the specific stone type to avoid excessive wear and tear. Understanding the material's characteristics will guide you in selecting a crusher from the AIMIX crusher plant company equipped with appropriate wear-resistant components and crushing mechanisms.

Evaluating Crusher Specifications

Crushing Capacity and Throughput

Crushing capacity and throughput are critical metrics when evaluating crusher specifications. These parameters determine the volume of material the crusher can process within a given timeframe. A crusher with higher capacity and throughput is essential for large-scale operations, ensuring that production targets are met consistently. However, it's important to balance capacity with operational efficiency, as excessively high throughput may lead to increased wear and maintenance costs. Analyzing the balance between capacity and efficiency will help in selecting a crusher that optimally supports your production goals.

Feed Size and Output Size Flexibility

The feed size and desired output size are integral factors in crusher selection. The crusher must accommodate the maximum feed size of the raw material while delivering the specified output size. Flexibility in adjusting the output size is advantageous for producing various aggregate grades. Crushers with adjustable settings allow for customization, ensuring that the output matches the specific requirements of different projects. This adaptability enhances the crusher's utility, making it a valuable asset for diverse quarrying operations.

Long-Term Considerations and ROI

Operational and Maintenance Costs

Long-term considerations, such as operational and maintenance costs, are vital in the decision-making process. While initial acquisition costs are important, the total cost of ownership encompasses ongoing operational and maintenance expenses. Efficient crushers with low maintenance requirements can significantly reduce downtime and operational costs, thereby enhancing profitability. Evaluating the total cost of ownership will provide a comprehensive understanding of the financial implications, ensuring a sound investment.

Future Scalability and Technological Advancements

Future scalability and technological advancements should also be factored into the equation. Investing in a crusher that can adapt to future production increases and incorporates cutting-edge technology ensures sustained operational efficiency. Technological advancements, such as automation and remote monitoring, enhance performance and reduce manual intervention. Considering future scalability and technology will ensure that the crusher remains relevant and efficient, supporting long-term aggregate production goals.