Crushing Collaboration: Leveraging Partnerships and Outsourcing in Crushing Plant Setup

Crushing collaboration in the realm of crushing plant setup isn't merely a strategy; it's a revolution. In the intricate dance of heavy machinery, raw materials, and intricate workflows, partnerships and outsourcing emerge as the unsung maestros orchestrating a symphony of efficiency and innovation.

The Power of Strategic Partnerships

Identifying ideal partners is the keystone of a successful stone crushing plant setup. The selection process is meticulous, requiring an alignment of vision, capabilities, and goals. Potential partners should not only bring technical expertise but also a shared commitment to quality and innovation. This synergy creates a foundation where ideas can flourish and challenges can be deftly navigated.

Benefits of collaboration in crushing plant setup are manifold. Firstly, shared expertise allows for more innovative problem-solving approaches, transforming potential bottlenecks into opportunities for improvement. Secondly, combining resources often results in cost savings, from shared equipment to reduced labor costs. Furthermore, strategic partnerships can lead to enhanced scalability. As demand fluctuates, having a reliable partner means your operations can adjust swiftly, maintaining efficiency and output.

Outsourcing for Operational Excellence

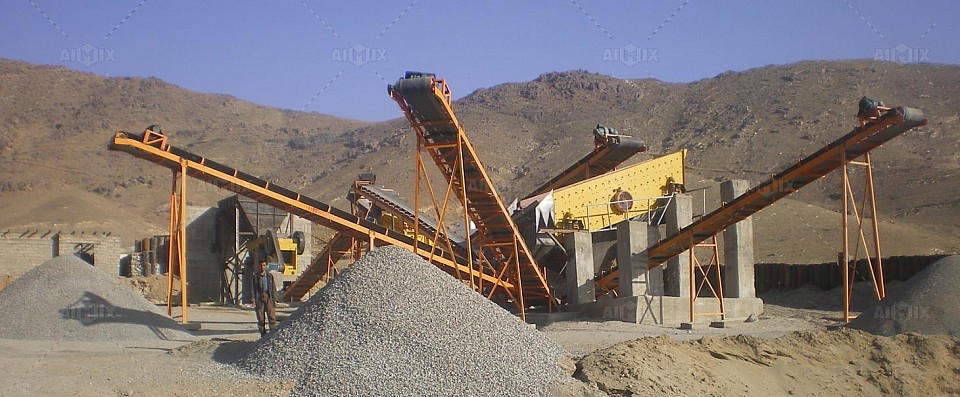

Selecting the right service providers is an art form in itself. It requires a deep understanding of your own operational needs and a keen eye for recognizing excellence in others. Look for providers with a proven track record in the crushing industry, a strong safety record, and a commitment to environmental stewardship. Their expertise should not only complement your operations but enhance them, providing services that are both efficient and innovative. You can choose AIMIX manufacturer, we will provide you with best service.

Enhancing efficiency and reducing costs through outsourcing is a game-changer. By outsourcing specific functions, such as equipment maintenance, material handling, or even certain administrative tasks, companies can focus on their core competencies. This focus leads to improved productivity and innovation within the main business areas. Outsourcing also provides flexibility, allowing companies to scale operations up or down without the burden of permanent overhead costs. The financial benefits are clear, but the operational advantages – streamlined processes, access to advanced technology, and specialized expertise – are equally compelling.

Harmonizing Partnerships and Outsourcing

Integrating collaborative efforts is the pinnacle of leveraging partnerships and outsourcing. It's about creating a seamless workflow where each collaborator's role is clearly defined and executed with precision. Regular communication, joint planning sessions, and shared objectives ensure that all parties are aligned. This harmony transforms potential friction points into nodes of synergy, driving the project forward with a unified momentum.

Case studies of successful implementations provide vivid illustrations of how these strategies come to life. Take, for example, a mid-sized aggregate producer who partnered with an engineering firm to design a state-of-the-art crushing plant. By outsourcing the maintenance and operational oversight to a specialized third party, they not only achieved a 20% increase in production efficiency but also significantly reduced downtime. Another instance is a construction company that collaborated with a local university to develop innovative recycling techniques for construction debris, transforming waste into valuable aggregate materials.

In the grand mosaic of crushing plant setup, the deliberate intertwining of partnerships and outsourcing paints a picture of enhanced capability, efficiency, and innovation. This approach doesn't just build plants; it builds future-ready enterprises poised for sustained success.